Our services

Design

Design

Our own patented construction technology allows us to prepare the construction project, to manufacture the structures in our workshop and to assemble various buildings on the construction site ourselves. We give priority to sustainable, ecological, economical and rational solutions. In this era of energetic and ecological challenges, it is very important to choose the right aesthetic and material means of realizing the philosophy of life. As we call out to the environment around us, we can expect a un/pleasant response.

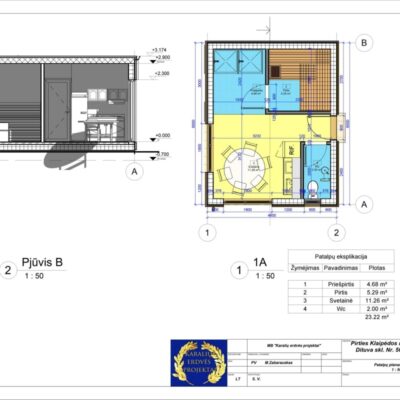

We prepare territory planning documents, construction or reconstruction projects of various buildings, we also take care of interior decoration or engineering solutions.

It is not necessary for you to have answers to all the questions that arise. That`s what we are professionals for. We can advise, give you the opportunity to see and touch the real product for you to make sure yourself. We consult during the entire construction process - starting with legal aspects, the selection of the plot, and finishing with interior solutions and premises. Modern digital technologies make it possible to see your dreams virtually, to modulate them, to choose from several options.

The decisive part of building a house is the project of course. During designing process, there is time to dream, search, change, solve, return, start or charge with good emotions otherwise before the most responsible stage - manifesting dreams on the construction site. It is said that paper will endure everything, and it is not worth experimenting and changing solutions during construction. The design phase requires the most patience, while the construction is precise and fast.

In the workshop, we manufacture building structures according to our own or other designers` designs. The patented assembly system of the building elements allows you to adapt various projects by converting them according to the module or by precisely fulfilling the builder`s ideas. It is possible to choose from already available repeatable projects.

Patented Building Construction Technology/System

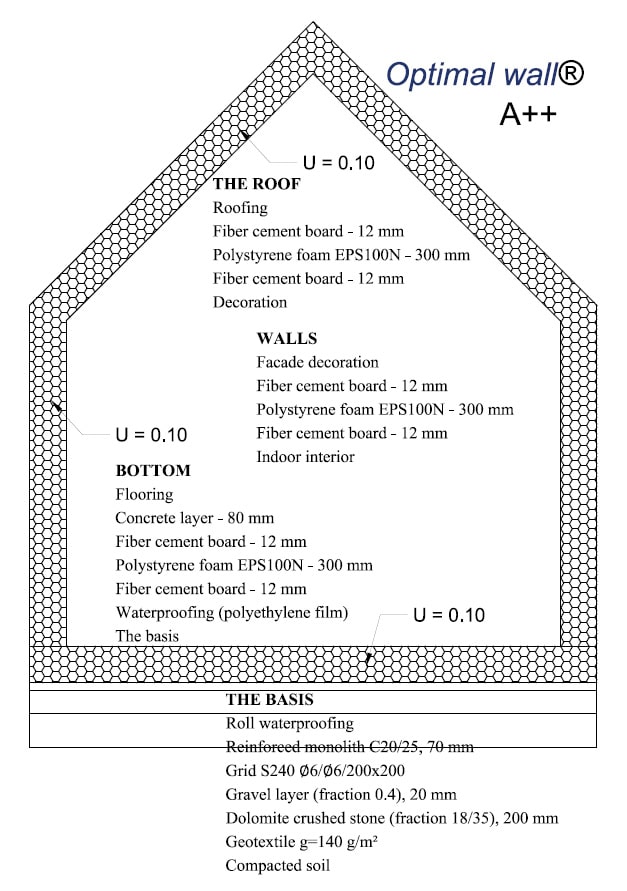

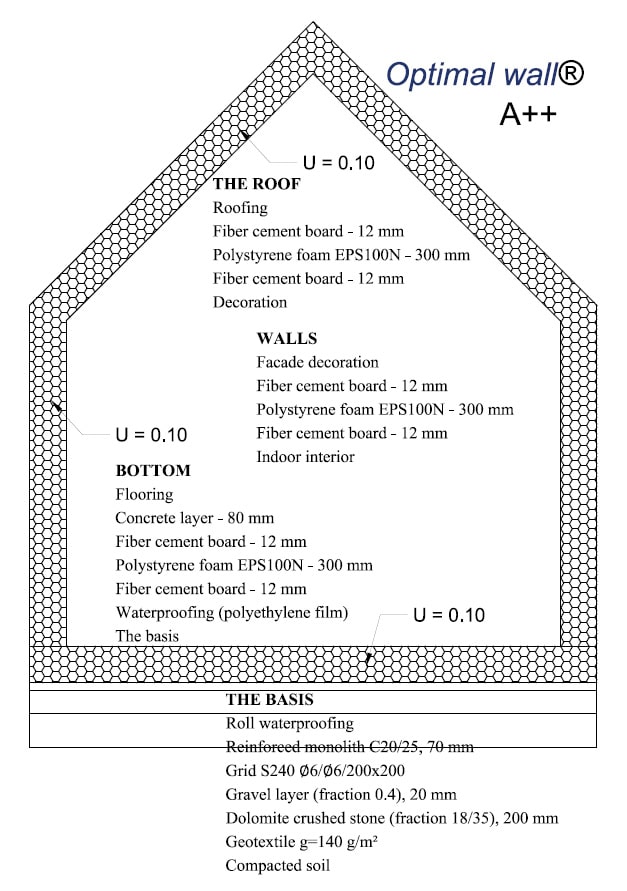

Optimal wall or optimal partition - only as much as needed:

1. Construction - the main three parts are manufactured in the workshop, i.e. structural insulated panels (SIP - structural insulated panel), I-joist and connectors. By connecting them together with nails, screws or wood screws, sealing with mounting foam, a frame-shell structure is obtained. The connection system is suitable for all types of buildings.

2. Various architecture and high energy efficiency buildings can be constructed using only three parts. There are no thermal bridges. One, two and more (requires additional supporting structure solutions) floors. The 3.0x0.6 m SIP panel corresponds to the strength modulus of the frame skeleton.

3. Blocks assembled from such details can be used for floors, walls, ceilings and roofs for the construction of residential, commercial or individual buildings.

4. The weight of the heaviest part is about 65 kg (140 lb), so it can be constructed without the use of mechanisms. Easy to transport.

5. The panels are standard and universal, so there is no need for a specific project – it’s been manufactured continuously to store them in the warehouse.

6. The traditional project can be converted by adapting to the structural module, reducing the number of individual parts.

7. The shell construction guarantees the spatial stability of the building, it is tight, light, warm (A++, passive) prefabricated. There’s no concentrated loads, no need for traditional foundations. Universal parts are suitable for the bottom, walls, and roof. There can be an integrated framework or a supporting skeleton separately, dressed in a "coat" of our panels. The only decoration remains.

8. The materials selected for the panels are stable, durable and ecological. Currently used:

9. It is necessary to prepare the site of compacted soil/gravel and bring the pipes of engineering networks.

Patented Building Construction Technology/System

Optimal wall or optimal partition - only as much as needed:

Unlimited Possibilities

Made in France

World-class Design